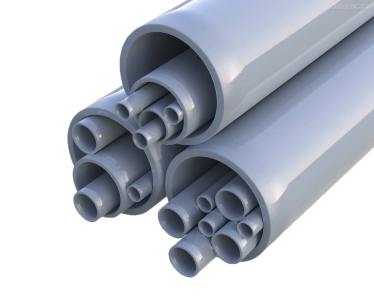

Certainly! Pipes and fittings are essential components in plumbing, construction, and various industrial applications. Here’s a detailed explanation:

Pipes

Definition:

Pipes are hollow tubes used to transport fluids (liquids and gases) from one location to another. They come in various sizes, materials, and types, each suited for different applications.

Materials:

Metal Pipes:

Steel: Durable and strong, used for high-pressure applications.

Copper: Resistant to corrosion, commonly used in plumbing.

Cast Iron: Used in underground drainage due to its strength.

Plastic Pipes:

PVC (Polyvinyl Chloride): Lightweight, easy to install, used for water supply and drainage.

CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but can withstand higher temperatures.

PEX (Cross-linked Polyethylene): Flexible, used for water supply systems.

Concrete Pipes:

Used in large-scale drainage and sewage systems.

Types:

Rigid Pipes: Maintain their shape and are used in fixed positions (e.g., PVC, metal pipes).

Flexible Pipes: Can bend and flex, used in applications where movement is expected (e.g., PEX).

Fittings

Definition:

Fittings are components used to connect, terminate, control the flow, and change the direction of pipes. They are crucial for creating a functional plumbing or piping system.

Types of Fittings:

Couplings: Connects two pipes of the same diameter.

Elbows: Changes the direction of the pipe, commonly available in 90-degree and 45-degree angles.

Tees: Allows branching of pipes; has one inlet and two outlets at 90-degree angles.

Reducers: Connects pipes of different diameters, reducing the flow from a larger pipe to a smaller one.

Adapters: Connects pipes of different types or materials.

Caps and Plugs: Used to close the end of pipes.

Valves: Control the flow of fluid through the pipe (e.g., gate valve, ball valve).

Materials:

Metal Fittings: Brass, steel, copper, and cast iron, used for their durability and strength.

Plastic Fittings: PVC, CPVC, and PEX, chosen for their corrosion resistance and ease of installation.

Applications

Residential Plumbing: Water supply, heating systems, drainage, and gas lines.

Industrial: Chemical transportation, oil and gas pipelines, and manufacturing processes.

Agricultural: Irrigation systems.

Municipal: Water treatment plants, sewage systems, and stormwater management.

Installation and Maintenance

Installation: Requires careful planning and knowledge of local codes and standards. Proper tools and techniques are essential to ensure a leak-free and durable system.

Maintenance: Regular inspection, cleaning, and occasional replacement of parts are necessary to prevent leaks, clogs, and other issues.

In summary, pipes and fittings are critical for creating systems that transport fluids efficiently and safely. The choice of materials and types depends on the specific requirements of the application, such as the type of fluid, pressure, temperature, and environmental conditions.