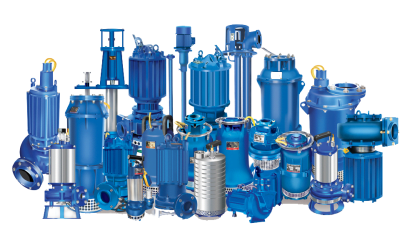

Pumps are mechanical devices designed to move fluids (liquids or gases) from one place to another, typically by creating a pressure differential. They are essential in various industries, including water supply, chemical processing, oil and gas, and many others. Here’s a detailed overview of pumps and their types:

Types of Pumps

Positive Displacement Pumps

Positive displacement pumps move fluid by trapping a fixed amount and then forcing (displacing) that trapped volume into the discharge pipe. They are generally used for high-pressure applications and can handle viscous fluids. Examples include:

Reciprocating Pumps: These include piston, diaphragm, and plunger pumps. They use a piston or diaphragm that moves back and forth to displace the fluid.

Rotary Pumps: These include gear, screw, and vane pumps. They use rotating mechanisms to move fluid.

Centrifugal Pumps

Centrifugal pumps use a rotating impeller to add velocity to the fluid and convert that velocity into flow. These pumps are commonly used for low-viscosity fluids and are suitable for high flow rates. Types of centrifugal pumps include:

Axial Flow Pumps: Use impellers with blades that push the fluid parallel to the pump shaft.

Radial Flow Pumps: The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing out radially.

Mixed Flow Pumps: Combine features of both axial and radial flow pumps.

Specialty Pumps

These pumps are designed for specific applications and can include:

Peristaltic Pumps: Use a rotating roller to squeeze a flexible tube, pushing the fluid forward. They are often used for pumping sterile or corrosive fluids.

Jet Pumps: Utilize a jet of fluid to create a vacuum that draws another fluid into the pump.

Submersible Pumps: Designed to be submerged in the fluid they are pumping, often used for water wells or sump pumping.

Key Parameters of Pumps

Flow Rate: The volume of fluid a pump can move per unit of time, typically measured in gallons per minute (GPM) or liters per minute (LPM).

Head: The height to which a pump can raise the fluid, usually measured in meters or feet. It represents the energy added to the fluid by the pump.

Power Consumption: The amount of energy consumed by the pump, typically measured in watts or horsepower.

Efficiency: The ratio of the hydraulic power delivered by the pump to the mechanical power supplied to the pump shaft.

Applications of Pumps

Water Supply and Treatment: Pumps are used in municipal water systems, irrigation, and wastewater treatment plants.

Chemical Processing: They handle the transfer of chemicals, often requiring corrosion-resistant materials.

Oil and Gas: Used for drilling, production, and refining processes.

HVAC Systems: Circulate water in heating and cooling systems.

Food and Beverage: Handle sanitary conditions for the transfer of liquids like milk, juice, and other beverages.

Maintenance and Troubleshooting

Routine Inspection: Regular checks for leaks, unusual noises, and vibration can prevent major issues.

Lubrication: Ensuring moving parts are properly lubricated can extend the life of a pump.

Seal and Bearing Replacement: Worn seals and bearings should be replaced to avoid leakage and maintain efficiency.

Performance Monitoring: Keeping an eye on flow rates, pressure, and power consumption can help identify when maintenance is needed.

Understanding the different types of pumps and their applications can help in selecting the right pump for a specific need and maintaining it properly for efficient operation.